About Industrial Fiberglass Woven Rovings

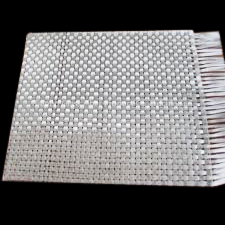

Fiber Glass Woven Rovings is composed of direct rovings woven into fabric or tape. The input rovings are designed to give controlled wet out and excellent lamination properties. Woven Roving Fabrics are designed to be compatible with multiple resin systems, and can be customized to meet specific product requirements.

Products Application :

Woven Roving Fabrics provide high-quality, global products designed to meet your performance and cost requirements. Woven Roving Fabrics provide the most economical solution for raising glass content of laminates and increasing laminate stiffness and impact resistance without adding thickness, weight, or other non-reinforcing materials. The fabric delivers cost effective solutions to your competitive reinforcement challenges, particularly large parts such as boat hulls and high-durability laminates such as underground storage vessels.

High-Performance ReinforcementThese woven rovings deliver exceptional tensile strength and dimensional stability, making them ideal for industrial reinforcement and demanding composites manufacturing. Their customized widths and thicknesses ensure they fit specific needs, from structural panels to tanks and pipes.

Superior Resin CompatibilityWith advanced surface treatments using silane or starch coatings, the rovings guarantee robust bonding with multiple resin types. This versatility streamlines production for laminates, pultrusion, and FRP applications, improving final product performance and reliability.

FAQs of Industrial Fiberglass Woven Rovings:

Q: How can Industrial Fiberglass Woven Rovings be used in manufacturing composites?

A: The rovings are integrated into composite production as reinforcement layers, offering structural integrity in laminates, boat hulls, automotive panels, and FRP applications. Their compatibility with polyester, epoxy, vinyl ester, and phenolic resins ensures seamless integration into diverse manufacturing processes.

Q: What benefits do plain and twill weave types provide?

A: Plain weave ensures consistent strength and uniform thickness, while twill weave offers greater drapability and conformability to complex shapes. Choosing between these weaves depends on application needs, balancing strength, flexibility, and surface finish.

Q: When should I use fiberglass rovings with a silane coating?

A: Silane-coated rovings are recommended when superior resin bonding and chemical resistance are necessary, particularly in environments exposed to moisture or aggressive chemicals. This coating enhances performance in demanding industrial and construction scenarios.

Q: Where are these woven rovings commonly applied?

A: They are widely employed in industries such as construction, marine, automotive, and piping for reinforcing panels, tanks, pipes, and structural composites. Applications extend to FRP manufacturing, pultrusion, and other industrial uses requiring robust reinforcement.

Q: What is the process for customizing dimensions of the woven rovings?

A: Manufacturers in India offer customization for length, width (standard 10002000 mm), and thickness (0.21.2 mm), allowing tailored solutions for various industrial applications. Customers can specify requirements based on their project and design needs.

Q: How does low moisture content and loss on ignition benefit product performance?

A: Moisture content 0.10% and low loss on ignition ( 1.0%) ensure dimensional stability, minimize risk of delamination, and enhance overall durability in harsh environments, making them reliable for long-term reinforcement in composites.